Functions Of Car Clutch And How Car Clutch Operates

The car’s transmission takes power from the engine to the road wheels. On a front-engine rear-wheel-drive car it consists of a clutch or a torque converter fixed to the engine flywheel, then a gearbox, propeller shaft and final drive unit which splits the output in half, to drive each rear wheel.

Some cars dispense with the propeller shaft by combining the engine and transmission into one power pack and mounting it between the driving wheels. This arrangement needs only two drive shaft to transmit power to the wheels.

HOW CAR CLUTCHES OPERATE

The clutch disconnects the engine from the road wheels when the driver is changing gear or bringing the car to a stop.

The clutch action can be likened to the operation of a sanding disc on a power drill.

If this is rotated and brought face-to-face with a separate stationary sanding disc, as the two faces meet the initial frictional contact will make the second disc turn slowly but as pressure is increased, both discs will turn at the same speed.

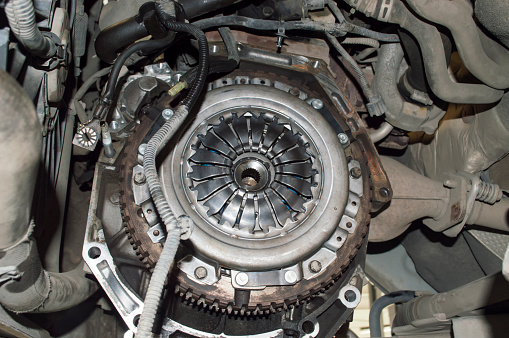

On a car engine, the same effect is achieved by sandwiching a friction-lined disc i.e. the driven plate which is attached to the gearbox input shaft between a pressure plate and the engine flywheel face.

The pressure plate is connected to a cover bolted to the flywheel. Operating the clutch pedal moves the pressure plate away from the flywheel, and the driven plate between them can rotate independently.

When the driver lifts his foot off the clutch pedal, the pressure plate moves towards the flywheel again, clamping the driven plate and linking the gearbox shaft to the flywheel.

Although it is possible to slip the clutch by partial operation of the clutch pedal, it is essential that the clutch does not slip when the pedal is fully released.

On most cars, the clamping load is applied by a powerful diaphragm spring, i.e. a cone of spring steel that is fitted so that at rest its outer rim pushes the pressure plate toward the flywheel.

Operating the pedal moves a thrust bearing against the center of the diaphragm, causing it to dish away from the flywheel, thus releasing the clamping load on the pressure plate.

Before diaphragm springs became available, a circle of coil springs bearing on the rear face of the pressure plate applied the clamping load.

HOW THE PEDAL IS LINKED TO THE CLUTCH

The clutch is operated either hydraulically or by a cable. On a cable system, a heavy-duty flexible cable is routed from the pedal through the bulkhead of the engine compartment and runs down the side of the engine to a clutch-operating lever.

At one end of the cable, there are adjusting nuts to compensate for any cable stretching.

Hydraulic clutch systems have a master cylinder connected to the pedal, attached by a hydraulic pipe to a slave cylinder which is joined to the clutch-operating lever.

CAR GEARBOX AND THE CLUTCH ARRANGEMENT

Because the internal combustion engine produces very little power at low speeds, it cannot be directly linked to the road wheels and must, therefore, be geared down.

At 70mph, for instance, most small cars have their engines running at about 4000 revolutions per minute while the road wheels are turning at about 1,000rpm.

The gearing-down is achieved by reduction gears in the final drive, and if the car traveled constantly at 70mph, this is all that would be needed.

However, besides traveling on motorways, the car must be able to start from a standstill and tackle steep hills. In order to keep the engine working at its most efficient speed under all conditions, all cars have a gearbox.

The most popular type is a manual gearbox which offers four choices of the gear ratio.

Gear ratios are determined by the number of teeth on meshing gear wheels.

If a gear wheel with 12 teeth is meshed with a gear wheel having 24 teeth, the smaller gear must rotate twice to turn the bigger gear once and the ratio of these two gears would be 2:1.

The final drive that reduces 4,000rpm at the heels has a ratio 4:1.

To move it from a standstill, the average small car has a bottom gear ratio of around 3.5:1. Other typical gearbox ratios are about 2:1 in second gear, 1.4:1 in third and 1:1 in top.

All these are in addition to the final-drive ratio, so with a pressing, the pedal forces fluid into the slave cylinder which operates the clutch.