Features Of Cartesian Robot And Its Applications

IMPACT OF INDUSTRIAL ROBOTS

Industrial robots brought the massive shift from manual production lines to automated production lines such that production rate increased and quality started improving leading to more market competition and drastic control of prices.

These benefits offered by the robots revolution or robot age had been appreciated only in a little approach such that only the industrialists seem to see and understand the immense value the robots are to the modern industries.

Such that, their absence would lead to a total shutdown of the entire factory.

How can a modern factory survive the huge market competition without robots?

Can quality and uniformity still exist accurately?

Can production costs still remain low in the absence of robotic productions? These questions are the fears of entrepreneurs who are running industries for profitability.

The robot has become such a vital aspect of human life that the benefits it offers remain hidden in the eyes of many consumers.

Meanwhile, in the eyes of a manufacturer, the robot is everything humans need for their survival.

The use of different types of robots for industrial applications has changed the automobile industries, metallurgical industries, electronics production firms, etc.

Micro-parts can be made accurately using Nanorobots while giant multi-task processing robots are being utilized by these industries for their production.

Above all the benefits, industrial automation has reduced the waste of raw materials.

Accurate measurement of raw materials and minimal waste after each production section had been a major features found in robotic production.

Such has offered the advantage to investors in making proper utilization of the fund they invested into the industry.

In every way it is viewed, robots are doing more good to humans than most people would think of which majority of the quality products with less price depend on the operations of the industrial robots.

Features of the Cartesian Robot a.k.a Cartesian Coordinate Robot

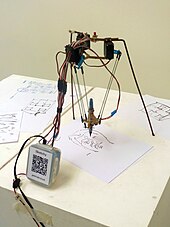

A Cartesian coordinate robot is a major type of industrial robots known for its linear operation.

It has three principal axes of control that move in a straight line rather than rotate and are in right angles to each other, such is known as the linear arrangement.

The job of moving the wrist up-down, in-out, and back-forth is based on the movement of the three sliding joints fixed accordingly.

The link arrangement of the robot offers many advantages against other types of industrial robots such that it simplifies the robot control arm solution.

A popular design of such robot has horizontal member supported at both ends and such is called Gantry robots, due to the fact that they resemble Gantry cranes in their mechanical design and links arrangement.

Although different designs are springing up, the Gantry robots are mostly large in size.

APPLICATIONS OF CARTESIAN ROBOT a.k.a CARTESIAN COORDINATE ROBOT

The modern CNC machines known as the computer numerical control machines and 3D printing technology make use of this type of industrial robot.

In other words, software used to operate CNC machines and 3D printing system can be synchronized into this robot to automate it and make it carry out specific tasks based on the available degrees of freedom in it.

The reality in this type of industrial robot is that almost all the modern complex industrial machines that are robotic are in this category of robot.

The most common application in industrial machines is the milling machines, shaping machines, and drawing machines, etc.

In its application in the drawing machine, a pen or router translates across the X-Y plane while a tool is raised and lowered onto a surface to create a precise design. Pick and place machines and plotters make use of the same principle.

Lathe production lines that have continuous parts loading and unloading make use of the robots in the sense that some of the machines in such line are Cartesian coordinate robots.

The principle of Cartesian coordinate robots is based on the 3 axes linear movement in the X, Y, and Z directions. Their high-speed performance saves the number of operators in any production lines.

The robot is also good in carrying heavy loads for pick and place or parts feeding actions and does such with accuracy in positioning and placement.

Some had been found to be operating with low noise but because of large size and complex parts, they seem to consume more power than other types of industrial robots.