What is Machine Maintenance and the Various Types Of Machine Maintenance

What is Machine Maintenance?

The term ‘maintenance’ had been explained in different terms by different authors, but basically, they are all saying the same thing.

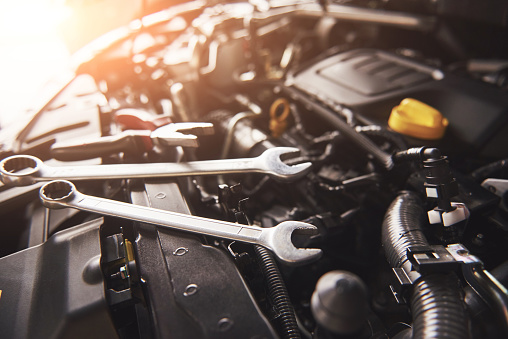

Maintaining a machine is different from repairing a machine and also different from the use of the machine at a lower load and time than specified.

Machine maintenance can be referred to as the entire process involved in the use of the machine to ensure its maximum efficiency, and durability, lower cost of operation and also guarantee the safety of the operators of the machine.

In other words, if a machine is being operated without good safety for the operators the machine is not under maintenance.

If the machine operating cost is high in terms of repair it is not under maintenance, if the efficiency had reduced at a high level it also shows it is not under maintenance.

Maintenance is a preliminary action on the machine to ensure steady functionality and durability, and ensure gradual deterioration of the machine lifespan. When these actions are put into place then a machine is said to be maintained.

There are different types of machine maintenance usually carried out by firms and large industries to ensure the continuous production and lower cost of their machine operation, because in the engineering belief “ it costs more to repair broken-down machine than to maintain it”.

We shall quickly discuss the different types of machine maintenance and how they are helping the machine durability, the rest shall be a topic for another day.

3 MAJOR TYPES OF ENGINE MAINTENANCE

PREVENTATIVE MACHINE MAINTENANCE

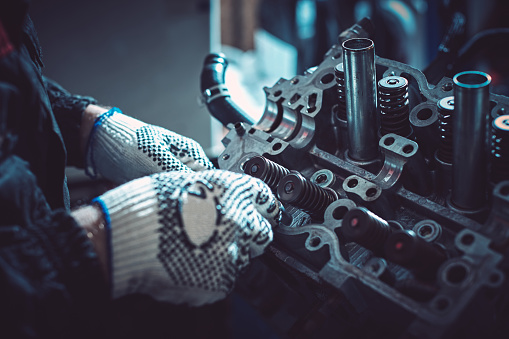

This is simply the servicing of the machine according to the procedures specified in the operator’s manual in order to prevent unexpected break-down or strange occurrences in the machine. In this type of maintenance, the activities involve:

Regular checking and addition of lubricants

Tightening of any loosened nut in the machine parts

Belt and pulley adjustment

Regular checking and adjustment of brakes, clutches, and safety devices

Possible part replacement,

Please note, that this maintenance is usually carried out in industrial machines to prevent the expensive cost of a complete shutdown of the plant, because in most cases the machine may be operational while the maintenance is being done.

Hence, referred to as preventive because of the purpose it tends to achieve.

PLANNED MACHINE MAINTENANCE

This is scheduled maintenance of a machine, targeted at specific periods of time. For instance, a firm may decide to use the first three days of every month for the planned maintenance of their machines.

In such a case, the machine may not actually have any fault or indicated any sign of power drop.

The sole purpose is to ensure that every part of the machine is in its normal condition and the records obtained are used to compare with the previous maintenance.

With that, any deteriorating part of the machine can easily be noted and a new part will be made available pro to the total damage of the existing part.

This maintenance is usually carried out at the shutdown state of the machine.

RANDOMIZED SHUT-DOWN MACHINE MAINTENANCE

Most industries have two or three machines performing the same function, and to ensure that each keeps working at a higher efficiency.

They are subjected to random shutdown maintenance in such cases each of the machines will be shut down and maintenance will be carried out on them at any interval of time according to the firms’ discretion.

SUMMARY

There are many types of machine maintenance not specified in this post, but at the basic, these are the things you need to know about machine maintenance, drop your comment for interaction.