Industrial Robots And Their Impacts

Facts About Industrial Robots

In terms industrial production activities and other minor jobs found in modern industries, robots have taken over 70 percent of them thereby reducing the human workforce, increasing production rate, and adding more untold advantages to the investors in the sector.

The underlying reasons for taking advantage of modern technologies are based on the numerous change robots has brought to the industrial sector.

Hence, the main reason for robotic production in terms of design and introduction of the robot into the manufacturing system is purely based on economic reasons.

The rapid inflation of wages experienced in the 1970s increased the personnel cost of manufacturing films, tremendously. At the same time, foreign competition became a serious problem for manufacturers in the United States.

Manufacturers who had undertaken automation on a wide scale basis, such as those in Japan, began to gain an increasingly large share of the United State and the world market for manufactured goods, particularly automobiles.

Through a variety of automation techniques including robots, the Japanese manufacturers as from the year 1970 were able to produce better automobiles more cheaply than the non-automated United states manufacturers who were continually engaged in the struggle with organized labor.

Consequently, in order to survive the market requirements, some manufacturers began to consider the new technological development that could help improve productivity and also produce better products at lower costs.

In the heat of all the industrial revolutions taking place, the main focus had been how to stand out in the increasing market competition among the manufacturers.

There were several steps taken by some manufacturers in order to introduce automation in the production system but those steps could be referred to as a semi-automation system.

It was observed that those ahead in the automation idea were making more profit, lower cost of selling and better product among other advantages. Just a few time ahead, other manufacturers saw automation as an idea that must be adapted.

The concept of industrial automation led to the idea of introducing robots into the manufacturing system.

The need to mass-produce uniform products without variation in quality pushed manufacturers’ efforts further toward the introduction of industrial robots.

With heavy financial commitments, the robots manufacturing industries moved their focus to the making of industrial robots to meet up with the demands of the manufacturers who want to stay ahead of others in any newly made industrial robots.

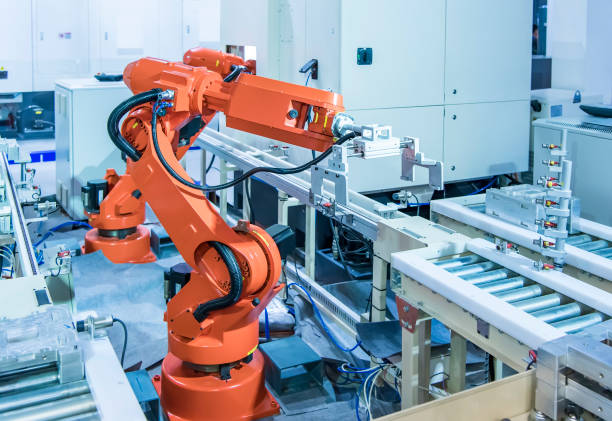

Currently, the industrial sector has been filled up with hundreds of robots performing different tasks for the industries.

At some stage, the focus moved towards accuracy, lower energy consumption, complex functionalities, and reliability to the modern age of artificial intelligence (AI).

So the manufacturers’ interest in these features forced robot developers’ effort further to find ways of satisfying their major clients which is the manufacturers.

Robots made the whole activities of the industries to appear simpler than those of the early industrial practices, manufacturers now have complete control of how they want their product to look, the level of its quality, material control, and reliable data that will not deceive their customers leading to loss of their integrity.

Majority of these data can be obtained even before the actual production occurs.

Other factors such as to find better ways of performing dangerous manufacturing task contributed to the development of industrial robots.

Some jobs which could be hazardous to human became a problem to manufacturers and employing anyone for such warrants heavy financial commitment.

Chemical industries and metallurgical industries were at the forefront for special industrial robots based on some tasks in those industries which could be very tedious and hazardous for a human to do.

Therefore, their aim was to displace humans doing such jobs with machines and that is part of the solutions that the modern industrial robots had provided.

Notwithstanding its above impact, the major principal aim and objective of the manufacturers had always been and still remain how to improve, increase, and stay ahead in terms of productivity.

The numerous impacts robots made in the industrial sector led to the rapid, current and projected growth of robot installations in many industries and even commercial firms.

The modern introduction of artificial intelligence robots is a step taken further to ensure superior industrial activities aimed at steady production system, reliability, and quality control among other vital reasons.

Top 14 IMPACTS AND ADVANTAGES OF INDUSTRIAL ROBOTS

All the impacts and advantages offered by industrial robots can be summarized as follows:

Industrial robots helped manufacturers increase their production with reduced manufacturing costs.

Robots made it possible for manufacturers to improve their product quality

The ability to retain consistency and uniformity in product quality is possible due to the presence of industrial robots.

Despite their tough, rugged and tireless characteristics, they can perform the hazardous and monotonous task with a tireless precision.

Industrial robots are capable of handling varieties of both simple and complex jobs.

They can cope with changing conditions in the work environment when fitted with sensors and adaptive controls.

Industrial robots helped the manufacturers reduce scrap and waste generation.

Industrial robots have helped the manufacturers save in direct labor cost based on the few workers needed.

Industrial robots have helped manufacturers reduce costs such as lighting, heating, and cooling which are part of maintenance activities for machines and tools used for the manual or semi-automated production system.

Industrial robots have helped to enhance safety in industrial practices leading to increased financial gain and fewer expenses in safety requirements.

They also offer an opportunity for multi-machine manning and even for a wholly unmanned production.

Where the shortage of human labor is a norm, robots become the next alternative for manufacturers.

Robots and its increasing development have become a source of encouragement to individuals to invest in the manufacturing sector.

Industrial robots made it possible to minimize space in the industrial and have a sequence mode of production that is fully automated.