Difference in Scara Robots and Delta Robots

The selective compliance assembly robot arm (SCARA) also stands for a selective articulated robot arm. It is a type of industrial robots classified based on its parallel-axis joint layout, the arm is slightly compliant in the X-Y direction but rigid in the Z direction.

The action of the arms led to the name “selective ….” Based on the fact that the movement is restricted to only two axes while the Z direction will remain static.

Such an arrangement gives the robot advantages for any types of industrial assembling operations.

The actions of inserting objects and tightening it or taking out a part and dropping it, etc. are among the simple tasks that best suit the robot model.

SCARA robot has limited applications when compared with the Delta robots based on the features the both can offer.

While they both could be made to have a similar look or appearance the major hidden difference could be the arms movement.

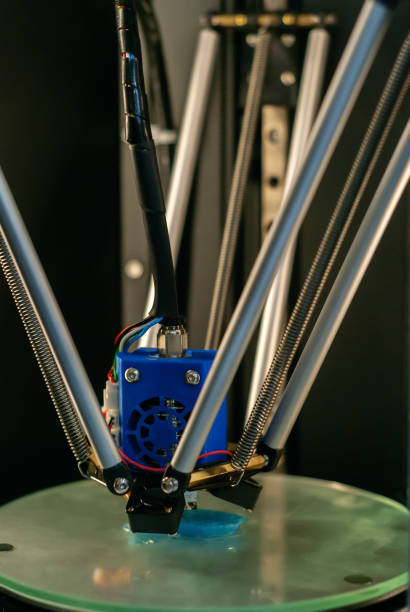

The delta robot’s arms movement could move in both the X, Y and Z directions while the SCARA’s will move in the X and Y directions while the Z direction will be rigid.

Some may not easily tell by mare-look ‘which is SCARA or DELTA’ when these two industrial robots are installed in a place except when they start operations their arms movement could help the viewer know the types.

SCARA has been found to be very useful for industrial tasks helping in places that accuracy and speed are required but with less sequence of operations.

The programming aspect of such a robot may be simpler than the Delta robots owing to the reduced flexibility of arms movement.

The best for stamping operations, cutting operation, tagging job, and punching works at its static position.

However, based on design and improvement, modern SCARA robots can be very versatile in operation especially when multiple arms and mobility are included.

Another common design feature for SCARA robots is that they usually have two-link arm layout similar to human arms that is why some people the robots “articulated robots”.

The feature allows the arm to extend into confined areas and then retract or ‘fold up’ out of the way.

Such feature gave it the advantage of being used for transferring of parts in the industries from one cell to another.

Besides that, stations such as an airport, seaport, and warehouses can use it for steady loading and offloading operations.

Experts said that the SCARA robots appear to be more clean, faster and smooth in operation than some industrial robots due to the few available axes of movement during their operation.

It is believed that their single pedestal mount requires a small footprint and provides an easy, unhindered form of mounting.

However, some believe such robot could be more expensive than others based on durability, reliability, speed, and less maintenance cost, etc.

Inverse kinetic software for linear interpolated moves is the controlling software for the SCARA robots and comes alongside the robots such that it is transparent to the end user.

Majority of this type of industrial robot was made based on the serial architectures that the first motor should carry all other motors. In the double-arm design, two of the motors are fixed at the base.

what is different between delta robot and scara robot

Please drop the comment on the Question page for further public answer