Safety Precautions When An Electrical Appliance Is Shocking

It is always a surprise to discover that the home electrical appliance that was working perfectly before have started shocking anyone that comes in contact with it.

Most users prefer to condemn and thrown such home appliances as a result of this problem. The reason for such decision is based on the belief that a shocking electrical appliance could be a total damage and unsafe to be used anymore. Well, such conclusion would better be decided by an expert.

Most common electrical shocking are the ones coming from electric cooking stoves, especially the type that has spring heating elements on its surface while the types with black carbon heating elements are lesser.

Another common electrical shocking comes from electric pressing irons especially when the cloth under it is still wet, even the shocking from water boiling rings is not excluded.

Common Questions Regarding Electrical Shocking

But the question is how do these electric shocking occur? Even when there is no sign of wrong connection or electric sparks within the wire connections around the building? What could cause such occurrences? How can it be stopped and be prevented?

How Do the Electrical Shocking occur?

Electrical appliance shocking is a common occurrence that can take place without giving out any physical sign. It usually occurs when there is a leakage of voltage and improper earthling of the electrical appliances.

When existing earthling has been damaged or a naked part of the live wire is touching metallic part of the electrical appliance, this will cause the entire body of the appliance to start shocking.

What could cause Electrical shock?

As mentioned earlier, the major cause electrical shocking is exposure to voltage. This could happen as a leaked voltage or full voltage depending on the root cause.

Electrical shocking caused by leaked voltage caused by earthling problem is usually minor compared to the one where a live wire is touching the metallic body of the electrical appliance.

How can Electrical Shocking be stopped and be prevented?

Electrical shocking can be stopped and be prevented by following the procedures listed below.

THE PROCEDURES:

CHECK IF WALL SOCKET IS THE SOURCE

You simply identify if the Source is from a wall socket by using another wall sock to check if the appliance will still shock. If the appliance is still shocking while inside another wall socket, the root cause maybe coming from the electrical appliance.

In that case, you need to focus tracing discontinuity or naked (uninsulated) part in the wiring of the electrical appliance.

Assuming you did not observe any shocking when you plugged the electrical appliance in a different wall socket, then it means the wall socket is faulty or something much bigger than that.

Some signs of wall socket being the root cause of electrical appliance shocking could also lead to the wet of the walls shocking as well.

CHECKING THE OVERALL JUNCTION BOX

This option will be followed after finding out that the electrical hocking is coming from the wall f the building and the wall socket instead of the electrical appliance.

Immediately remove the fuse of the line supplying power to the whole building. Ensure the building has no trace of electric voltages.

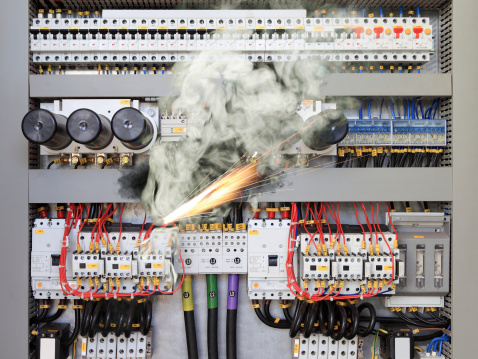

Then open the major junction box supplying voltage to the rest of the junctions for distribution in various apartments and units to trace the fault.

But if nothing visible was found, no trace of burnt wire or sparked edges, check all other junction boxes and if yet nothing is indicating any sign of a fault in the wiring i.e. if everything in each junction box appeared normal.

DISCONNECTING JUNCTION BOXES

Start disconnecting the junction boxes one after the other to isolate each one from the next linking point for easy testing of any discontinuity.

Basically, it can be assumed that such shock may be coming from an earthed wire that has established contact with the live wire in the building. But the problem at this moment is how to identify where this contact has been established.

USE A DIGITAL OHMMETER

An ohmmeter is an electric device used to measure the resistance of any conductor and it has both the digital type and analog types of it.

You can take about 50meters long of small red and black color wire, fix the ends of the wires in each of the two junction boxes to color code it and identify which one is having discontinuity or contact with the earthed line.

This should be carried out to about 20 junction boxes in the building and should be done carefully. If you are able to identify the point of discontinuity in any of the wire, then the source of the problem has been identified.

TESTING FOR FAULT RATIFICATION

Having found discontinuity or a naked portion of the wire establishing contact with the wall of the building or the electrical appliance, the next action is to correct the error by establishing insulation in that portion and then test for fault ratification afterwards.

CHECKING FOR THE CAUSES

Having confirmed the ratification, it is necessary to find out the possible reason the first burning of the wire insulator. Most ties this is caused by overloading.

This implies that the workload in the wall sockets are more than the wire capacity thereby causing it to generate excessive heat that led to the burning of its plastic insulator and exposed the uninsulated part of the wire to the body of electrical appliance or building wall.

To check for the causes, look into the possible load that the live wire could carry to generate such heat that could melt its insulator. The information obtained here can be used to specify the actual type of electrical appliance that should be plugged in the socket.

Conclusion

Having employed all the above safety precautions when an electrical appliance Is shocking and the problem is not yet resolved; use the comment section to reach out to us for further support.