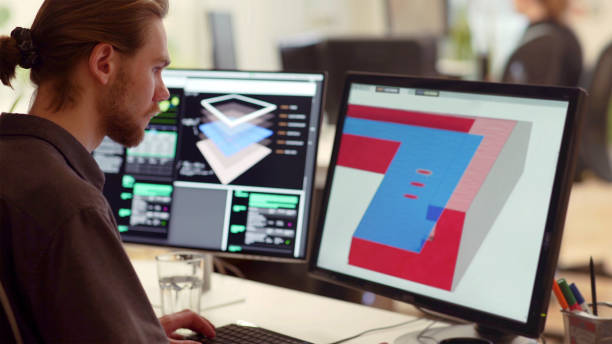

Way To Understand CAD/CAM Database

Industrial revolution over the years and the need to improve in the quality of products among other rising issues prompted the software engineers to device means of making manufacturing to become easier, efficient, and substantial reduction of errors caused by human factors.

Using the CAD/CAM in modern manufacturing processes is no way a surprise to the engineers since it had been a long-awaited prediction subjected earlier with series of testing and experiments before reaching to its current age of perfection.

CAD/CAM is the only system that has thoroughly replaced most of the human activities in production lines. It introduced a new level of speed in industrial production coupled with accuracy and precised dimensions leading to uniformity in batches of different products.

Though it took a long time to become the center of the industrial systems, the impacts it has made in modern engineering has paid off.

CAM/CAM system will not make a particular product to be produced in batch with uniform dimensions, it has the ability of storing the data of the product for future use in the case an occasion calls for it.

CAD offers the opportunity to develop the database needed to manufacture any product which is the main reason for its development.

Before now, the primitive method use engineering drawing prepared by a design draftsman and then forwarded to the manufacturing team to develop the process plan. It is a two-step process which are design and manufacture.

However, in CAD/CAM integration, the aim is to automate some parts of the whole processes involved in getting the final product.

It automates certain faces of the designing job and those of the manufacturing operations. The system ensures full transmission from design to manufacturing.

A computer-based system plays its role by creating much of the data and documentation required to plan and manage the manufacturing operations for the product.

THE MANUFACTURING DATABASE

The manufacturing database which is an integrated CAD/CAM database includes:

- All the data on the product generated during design such as geometry, bill of materials, part lists, material specifications, etc.

- Additional data required for manufacturing that product design.

SUMMARY

In modern engineering, it is possible to integrate the robot into factory CAD/CAM database and information system. The design engineering and process planning functions provide the inputs for engineering and manufacturing database.