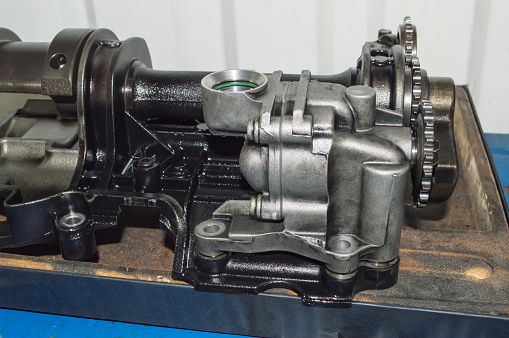

FEATURES OF ENGINE OIL PUMP AND ITS WORKING PRINCIPLES

In the simplest form, an engine oil pump consists of two gear wheels meshed together in a tight space so that oil cannot escape past the sides.

One wheel is driven by the engine and as they rotate in opposite directions, the dwell or recess between each tooth in each wheel traps a small quantity of oil from an inlet port.

The trapped oil is carried around by each wheel towards an outlet port on the opposite side of the casing, where it is forced out by the meshing teeth.

The principle of squeezing oil from an ever-decreasing space is used in the rotor-type pump. Here an inner and outer rotor are mounted on different axes in the same cylinder.

The inner rotor, which commonly has four lobes, is driven by the engine. It meshes with an outer rotor that has five lobes.

As they rotate, the spaces between them vary in size. The intake port is placed at a point where the space between the rotor lobes is increasing, drawing oil in.

It is then carried around the pump, and as rotation continues, the space between the lobes gets smaller, compressing the oil which is then ejected through the outlet port.

IMPACT OF OIL PUMP ON CRANKSHAFT MOTION

To enable a shaft to rotate easily, every bearing has a small clearance. A crankshaft bearing is usually 2 inches i.e. 50.8mm in diameter and would have a clearance of 0.003in i.e. 0.076mm.

When the engine is at rest, the heavy crankshaft sits at the bottom of the bearings, leaving most of the clearance at the top.

Once the engine is started, for the first few seconds, a thin beam of residual oil prevents possible ‘metal-to-metal’ contact until oil under pressure arrives from the oil pump.

Once the bearing is full of oil, the rotating shaft drags oil molecules around with it.

As they approach the narrowest clearance near the bottom of the bearing, they pile up and form a wedge which forces the shaft and bearing apart.

The action of the oil wedge means that the crankshaft literally floats in oil once the engine is running.

In theory, this floating action means that the crankshaft bearings should never wear out, but they do.

WHY CRANKSHAFT BEARINGS WEAR AWAY

In a practical approach, the bearing does wear out.

For instance, when there is a low oil level in the sump and when a car with a sump only partly full of oil is cornered, the oil moves away from the pump pick-up and for a few seconds, air instead of oil is pumped to the bearings.

If this happens often enough, the metal-to-metal contact increases the bearing clearance, and eventually, most of the oil spills out of the side of the bearing instead of forming the oil wedge that supports the crankshaft.

Once this stage is reached, the engine makes a rumbling or deep knocking sound on acceleration as the bearing surfaces hammer together.

It is usually necessary to regrind the crankshaft journals and fit new undersized bearings to get things back to normal.

Hint: “The stationary crankshaft journal rests on a thin oil film in the bottom of the shell bearing. Once the crankshaft starts rotating, it drags oil into the pressure area which lifts the shaft off the bearing.”